How TReGo Bike Trolley is Made

Turned idea into reality

Dear TReGo Friend,

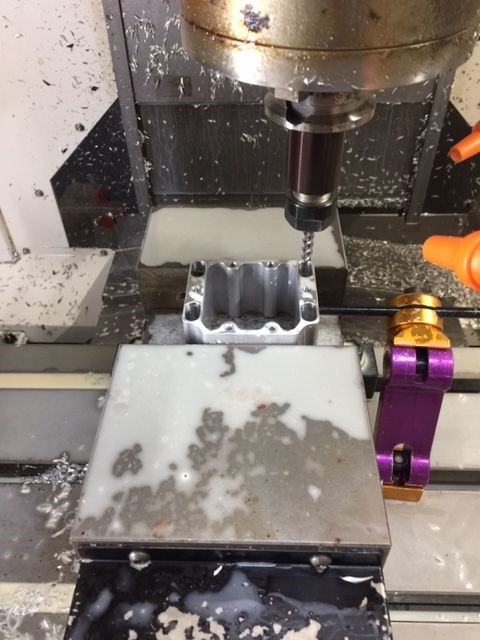

Drilling, cutting, sanding the machines in the factory hardly have a break. We thought it would be interesting for you to have a look behind the scenes of how TReGo is made.

Many parts of TReGo are custom made by CNC machines. CNC enable us to build complex forms with high accuracy automatically.

On the pictures you can see how the main body of TReGo is build and how the tilting arm looks before it is been weld together and gets a black anodize surface treatment…

It is an exciting process and we are already looking forward for the next step of the production where the parts are going to be weld together and get color.

Of course we will send you an update as well.

Source by TReGO-Trolley

Learn more about IRWIN bicycle product design and development or cycling product sourcing services